Essential Wire Gauge Chart: Understanding AWG and Ampacity Basics

Posted by Jacob Morris on Jan 11th 2026

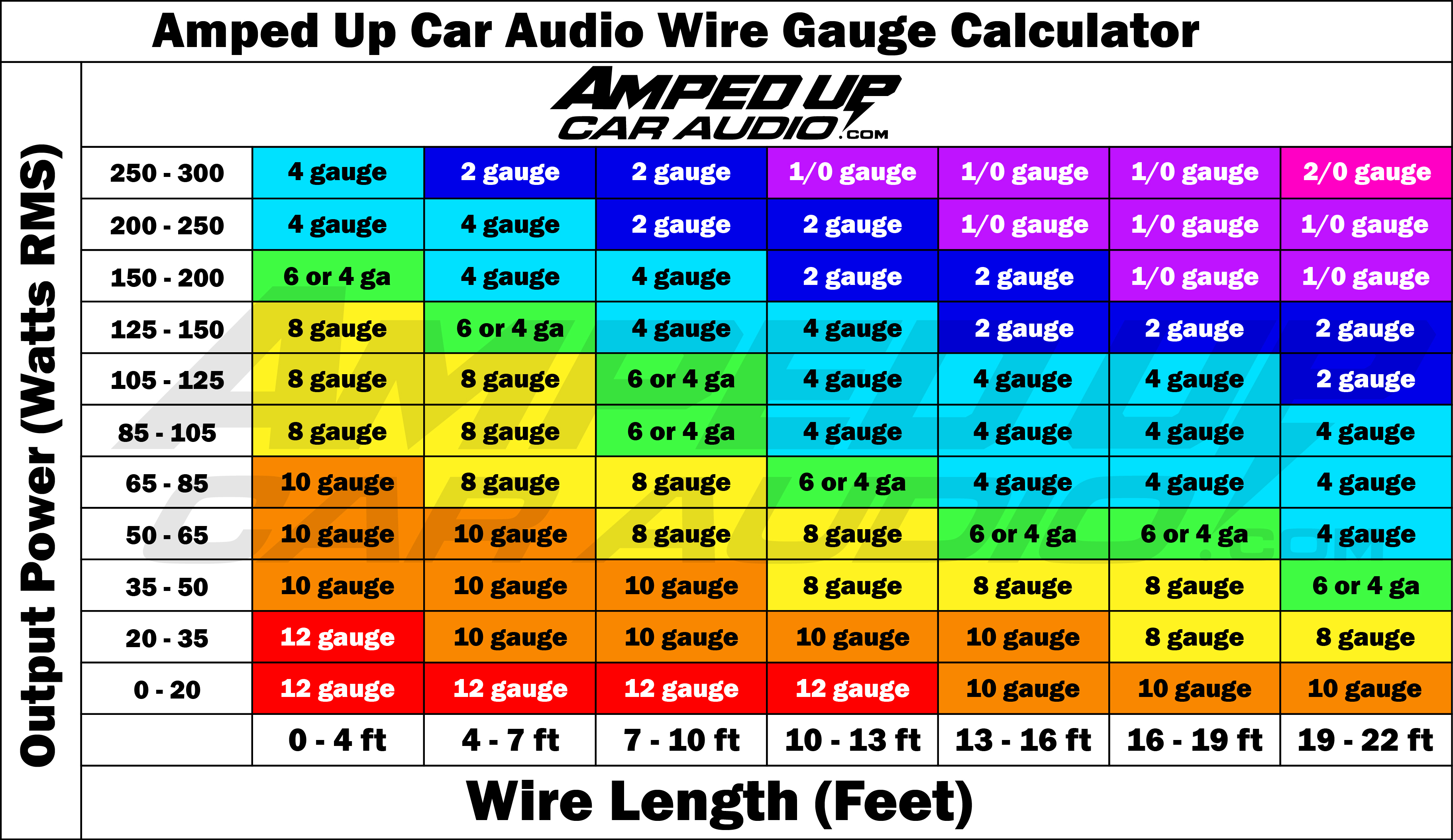

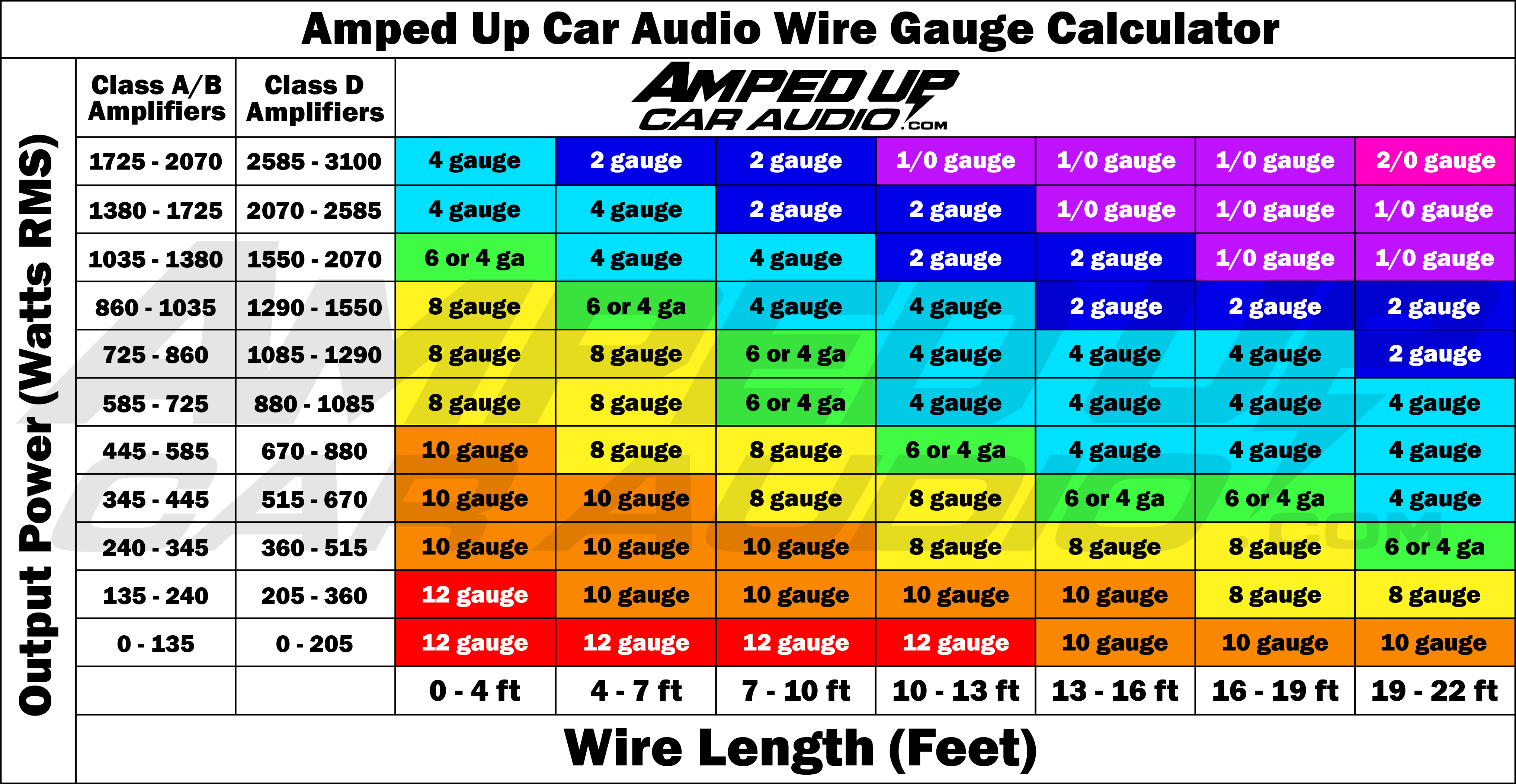

Wire Gauge Chart for Amplifiers (Power & Ground)

Introduction to Wire Gauges

The American Wire Gauge (AWG) system is the industry standard for measuring the diameter of electrical wires, especially copper wire, in North America. Whether you’re working on chassis wiring, power transmission, or lighting circuits, understanding wire gauge is essential for building a safe and efficient system. Each AWG number corresponds to a specific wire diameter, and as the gauge number decreases, the wire gets thicker—allowing it to carry more current with less voltage drop.

This guide is for car audio enthusiasts, installers, and anyone needing to select the right wire gauge for amplifiers and power systems. We cover power and ground wire sizing, ampacity, and best practices for safe installation. This guide includes a comprehensive wire gauge chart to help you choose the right size for your amplifier power and ground wiring. A quick-reference chart is included below for your convenience.

By understanding how gauge numbers relate to wire thickness and maximum current, you can make informed decisions that protect your gear and optimize performance across your entire electrical system.

Wire Gauge Chart (Quick Reference)

For users who want a fast answer, use this summary chart to match your amplifier’s current draw and wiring run length to the recommended wire gauge:

Understanding Copper Wire

Copper wire is the backbone of reliable power delivery in automotive audio systems, as well as in countless other electrical applications like power transmission, lighting circuits, and chassis wiring. Its superior conductivity and flexibility make copper the preferred material for both professional installers and car audio enthusiasts who demand clean, consistent power flow.

To standardize wire sizes, the industry uses the American Wire Gauge (AWG) system. In this system, wire gauge numbers are inversely related to wire diameters—meaning a lower AWG number indicates a thicker wire. For example, 1/0 gauge copper wire is much thicker and can handle more current than 8 gauge or 12 gauge wire. This is crucial when planning your system, as the correct wire size ensures your equipment receives the voltage and current it needs without excessive resistance or dangerous overheating.

When selecting wire for power transmission, lighting circuits, or chassis wiring, always consider both the AWG diameter and the specific requirements of your system. Using the right gauge wire not only maximizes performance but also protects your investment by preventing voltage drop, power loss, and potential damage to your audio components. Whether you’re wiring a high-powered amplifier or upgrading your vehicle’s lighting, understanding copper wire and the AWG system is the first step to a safe and powerful installation. In many electrical systems, the lead wire—the primary conductor supplying power—must be carefully selected to ensure it can handle the required load without excessive voltage drop or safety risks.

Transition: Now that you understand the basics of copper wire and the AWG system, let’s quickly determine what size power and ground wire you need for your amplifier setup.

Quick Answer: What Size Power & Ground Wire Do I Need?

Your amplifier wire gauge depends on three things:

-

Total amplifier RMS wattage (not max/peak)

-

Approximate current draw (amps) your system will pull

-

Length of the wiring run (battery → amp location)

The longer the run and the higher the current, the bigger the wire needs to be.

Transition: Now that you know the key factors, let's look at the properties of copper wire and how gauge affects performance.

The Beginner-to-Expert Guide to Choosing the Right Amp Wiring Size (With Wattage + Amperage Charts)

If you’ve ever Googled “what wire gauge do I need for my amp?” or “4 gauge vs 8 gauge amp wire”, you’re not alone. Using the wrong power/ground wire size is one of the fastest ways to get voltage drop, dimming lights, amp protect mode, clipping, hot wires, blown fuses, and weak performance.

To determine the correct wire gauge for your car audio system, you need to know how many amps your setup will draw—this is called the wire's ampacity. Ampacity refers to the maximum amount of electrical current a wire can safely carry without overheating, and is affected by factors like wire size, material, and installation conditions.

This guide breaks it down step-by-step, then gives you the wire gauge chart you can actually use—including a wattage-to-wire chart and an amperage (current draw) chart.

At Amped Up Car Audio, we stock wiring, electrical upgrades, and install essentials to build it the right way the first time.

Transition: Let’s start by calculating your system’s total RMS wattage, which is the foundation for all further calculations.

Step 1: Add Up Your Total RMS Wattage (Do Not Use Peak)

Calculating RMS Wattage

Calculate the total RMS output of your system:

-

4-channel amp: channels × RMS per channel

-

Monoblock sub amp: use the rated RMS at your final load

-

Multiple amps: add the RMS totals together

Example:

-

4-ch amp: 100W × 4 = 400W RMS

-

Sub amp: 1500W RMS

-

Total system = 1900W RMS

Transition: With your total RMS wattage in hand, the next step is to estimate your system’s current draw in amps.

Step 2: Estimate Current Draw (Amps) the Right Way

Estimating Current Draw

This is what most people skip. Wire is sized for amps, not watts. The correct conductor size is chosen based on the current requirements of the circuit, and you need to account for all relevant factors when estimating current draw.

The formulas we use (real-world safe)

We assume the vehicle is running at 13.8V (more realistic than “12V”).

The current draw is calculated using formulas that take the form of RMS Watts divided by voltage and efficiency.

-

Class D amps (more efficient): Amps ≈ RMS Watts ÷ (13.8 × 0.75)

-

Class AB amps (less efficient / safest estimate): Amps ≈ RMS Watts ÷ (13.8 × 0.50)

If you don’t know your amp class or you have a mix, use Class AB for the safest result.

If you’re unsure about the difference between peak and RMS Power and why RMS is the correct figure to use for wiring sizing, check out our detailed explanation here: Peak vs RMS Power in Car Audio: What’s the Real Difference?

Amperage Chart (Watts → Estimated Amps)

The following table provides ampacity values based on data and specifications from manufacturers. Use this to estimate how much current your system can pull at full tilt.

|

RMS Watts |

Class D (≈75% efficient) |

Class AB (≈50% efficient) |

|---|---|---|

|

500W |

48A |

72A |

|

1000W |

97A |

145A |

|

1500W |

145A |

217A |

|

2000W |

193A |

290A |

|

3000W |

290A |

435A |

|

4000W |

386A |

580A |

This is why big builds need bigger wire, solid grounds, and usually Big 3 + HO alternator + battery reserve.

(The Big 3 refers to upgrading the three main charging wires in a vehicle; HO means high-output alternator. Learn more about the Big 3 upgrade.)

Transition: With your estimated current draw, you’re ready to select the correct wire gauge using the chart below.

Best Wire Gauge Chart (Power & Ground Wire Size)

Important Notes

-

This chart shows ampacity values for conductors based on AWG wire sizes. Ampacity is the maximum current a conductor can safely carry, and is affected by ambient temperature and temperature. The process of derating is necessary when conductors are bundled or exposed to high temperatures; these conditions are noted in the chart where applicable.

-

This chart is for stranded copper wire only (OFC/tinned copper). Aluminum conductors have different ampacity values and require special fittings and anti-oxidant paste for safe use.

-

CCA wire cannot carry the same current as copper—if you’re running CCA, you generally need to size up.

-

Power AND ground should be the same gauge.

-

If you’re on the line between two sizes → go bigger.

-

Wire diameters are measured in inches or millimeters, and circular mils are another commonly used unit for conductor size in North American electrical systems. Wire weight can also be relevant for certain applications.

-

The chart is based on accurate data and commonly used industry standards for AWG wire, but always refer to manufacturer specifications for details and safe installation.

-

Fine wire (very small gauge) is used in specialized applications and may require additional consideration for ampacity and installation.

-

The AWG system has its own definition and is different from British and Brown & Sharpe (brown) gauge systems, which have separate standards and measurement processes.

Recommended Wire Sizes

|

Run Length (ft) |

Max Amps |

Recommended Gauge |

|---|---|---|

|

0–10 |

Up to 60 |

8 AWG |

|

0–10 |

Up to 100 |

4 AWG |

|

0–10 |

Up to 250 |

1/0 AWG |

|

0–10 |

Over 250 |

2/0 AWG (or dual 1/0) |

|

10–16 |

Up to 40 |

8 AWG |

|

10–16 |

Up to 80 |

4 AWG |

|

10–16 |

Up to 200 |

1/0 AWG |

|

10–16 |

Over 200 |

2/0 AWG (or dual 1/0) |

|

16–20+ |

Up to 30 |

8 AWG |

|

16–20+ |

Up to 60 |

4 AWG |

|

16–20+ |

Up to 150 |

1/0 AWG |

|

16–20+ |

Over 150 |

2/0 AWG (or dual 1/0) |

This is a conservative, real-world chart designed to reduce voltage drop and keep installs safe.

Transition: If you prefer to size your wire based on amplifier wattage, use the following wattage-to-wire chart for a quick answer.

Wattage-to-Wire Gauge Chart (Easy “What Wire for My Amp?”)

If you just want the quick “what gauge wire for my amp wattage” answer, use this.

Under 600W RMS (small systems)

-

Typical wire: 8 gauge

-

Upgrade to 4 gauge if the run is long or you want extra headroom.

600W–1500W RMS (daily driver sweet spot)

-

Typical wire: 4 gauge

-

Consider 1/0 gauge if you’re 1200–1500W and the run is long.

1500W–3000W RMS (serious daily / demo)

-

Typical wire: 1/0 gauge

-

Big 3 strongly recommended.

3000W+ RMS (high current builds)

-

Typical wire: 2/0 or dual 1/0

-

Big 3 required, and electrical upgrades are usually mandatory.

Pro tip: wattage charts work best when you also check current draw (amps), because efficiency and voltage matter.

Transition: Next, let’s see why wire length is so important and how voltage drop can affect your system’s performance.

Why Wire Length Changes Everything (Voltage Drop Explained)

Longer wire = more resistance = more voltage drop.

That means:

-

The amp sees less voltage

-

It draws more current to try to make power

-

Your system clips sooner

-

Your wire heats up

-

Your electrical gets stressed

If you’re mounting an amp in the trunk and your battery is in the engine bay, always size wire for the longer run.

Transition: Now, let’s look at the various applications for AWG wire and why correct sizing is critical in different scenarios.

AWG Wire Applications

AWG wire is used in a wide variety of applications, from residential lighting circuits to heavy-duty power transmission in commercial and industrial settings. Choosing the correct AWG wire size is crucial for preventing voltage drop, avoiding overheating, and ensuring that the maximum current rating of the wire is never exceeded. In lighting circuits, for example, using the right AWG wire helps maintain consistent voltage and prevents dimming or flickering caused by excessive resistance.

In power transmission and high-current applications, selecting the appropriate AWG wire size minimizes energy loss and ensures reliable operation of all connected equipment. Electricians, engineers, and technicians depend on accurate wire sizing to meet safety codes and deliver dependable performance. Whether you’re wiring a car audio system, upgrading home circuits, or designing industrial control panels, understanding the specific requirements of each application—and matching them with the correct AWG wire—ensures your system operates safely and efficiently, without the risk of overheating or electrical failure.

Transition: To keep your installation safe, don’t forget about proper fusing—let’s cover the essential fusing rules next.

Fusing Rules (Don’t Skip This)

Power wire must be fused as close to the battery as possible.

General rule:

-

Fuse size should protect the wire, not “match the amp.”

If you’re using an amplifier wiring kit, run the fuse that comes with the kit or size it according to the wire manufacturer’s recommendations.

All fusing and wiring should comply with the National Electrical Code, and consulting a qualified electrician is recommended to ensure safe installation.

Transition: Now, let’s quickly review speaker wire sizing for optimal audio performance.

Speaker Wire Size Guide (Quick + Simple)

Proper speaker wire sizing is crucial for audio electronics, ensuring optimal speaker performance and reliability. This standard practice is not only essential for car audio systems but is also widely used across many industries, including robotics, automation, and manufacturing, where precise wiring is critical for various electronics applications.

Speaker wiring matters too—especially subs.

-

Door speakers: 18 / 16 / 14 gauge

-

Subwoofers: 16 / 14 / 12 gauge

-

Long runs or high power → go larger

Transition: To wrap up, let’s review the best practices for choosing wire gauge and answer some common questions.

Conclusion and Best Practices

Choosing the right wire gauge is one of the most important steps in any electrical or car audio installation. Using the American Wire Gauge system, you can accurately determine the correct wire size for your specific needs, taking into account factors like current draw, voltage drop, and run length. Always refer to up-to-date electronic tables, manufacturer specifications, and the National Electrical Code to ensure your installation meets safety standards and delivers reliable performance.

For best results, use high-quality copper wire, size up when in doubt, and match your power and ground wire gauges. Pay close attention to ambient temperature, conductor size, and the total load on your system to prevent overheating and voltage loss. If you’re ever unsure, consult a professional or reach out to the experts at Amped Up Car Audio for guidance. With the right wire gauge and careful planning, you’ll protect your investment, maximize your system’s output, and enjoy clean, powerful sound for years to come.

FAQ (Google “People Also Ask” Targets)

What gauge wire do I need for a 1000 watt amp?

Most installs are 4 gauge copper, but confirm run length and your amp’s class. If you’re long-run or pushing hard daily, 1/0 is never a bad move.

Is 4 gauge enough for a 1500 watt amp?

Often yes for copper wire on shorter runs, but many 1500W setups do better with 1/0, especially in SUVs/trucks.

Can I use 8 gauge wire for an amp?

Yes—for small amps and lower current builds. Once you’re climbing in power or run length, 4 gauge is usually the better move.

Power and ground wire the same size?

Yes. Your ground path matters just as much as your positive.

Check out these articles to learn more.

Add these sections as clickable links on your site:

-

Big 3 Upgrade Guide (recommended in every wiring article)

-

How to Choose the Right RCA Cables

-

How to Choose the Right Battery for Car Audio

Written by Jacob Morris

Audio Expert & Co-Owner of Amped Up Car Audio